- About Ajou

- Admission

- Academics

- Research

-

International

International

- Campus Life

-

News and Event

News and Event

-

AUT

AUT

Ajou News

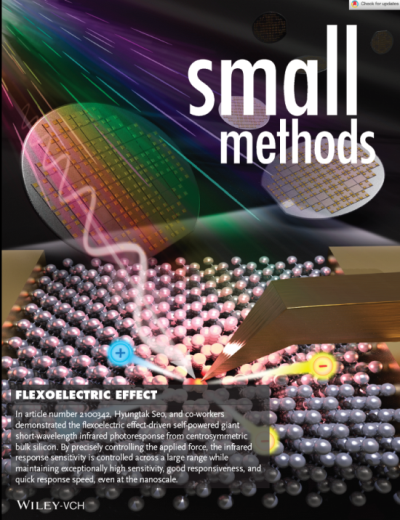

NEW Prof. Seo’s Research Team Develops Silicon Semiconductor-based High-Performance Infrared Photodetector

- 2021-09-06

- 4020

An Ajou University research team has developed a silicon semiconductor-based high-sensitivity infrared photodetector. The technology will be applied to a variety of fields that require high-sensitivity and high-efficiency infrared sensors, such as autonomous vehicles, solar cells, and medical diagnostic devices.

Prof. Seo Hyung-tak (Dept. of Materials Science Engineering, Graduate School Department of Energy Systems Research) of Ajou University announced his team’s success in developing a high-performance silicon-based infrared light sensing device using flexoelectricity that is formed when the semiconductor crystal structure is strained.

The related study was published in the online edition of Small Methods (IF=14.188), an international journal in the nano field, under the title, “Controllable, Self-Powered, and High-Performance Short-Wavelength Infrared Photodetector Driven by Coupled Flexoelectricity and Strain Effect” on July 19, 2021. The thesis was featured on the issue’s front cover. Prof. Mohit Kumar (Graduate School Department of Energy Systems Research) and Prof. Park Ji-yong (Department of Physics, Graduate School Department of Energy Systems Research) took part in the research as first authors.

Optical sensors based on the photoelectric effect that converts light into electrical signals (a method that detects photocurrent by the movement of electrons and holes formed by light) are essential part to the utilization of new and renewable energy, smartphones, the Internet of Things (IoT), and optical communication. Infrared light detection has the widest application and is used not only for thermal imaging in the medical field and night vision but also as a front sensor for autonomous vehicles and object movement detection. Although there are various operating principles in an optical sensor for detecting infrared light, the method using the photoelectric effect generated by direct absorption of infrared light shows the highest sensitivity. This method can also have high value-added applications. However, in order to manufacture such a photoelectric effect, the band gap of the light-absorbing semiconductor (minimum energy required for a semiconductor material to absorb light) must be lower than the infrared light energy. For this reason, gallium arsenide and other compound semiconductor devices have been the main choice so far. However, such compound semiconductor devices are very expensive, have low detection sensitivity in the infrared region, and are limited in performance.

Ajou University's research team focused on silicon, which had not been used as an infrared sensing material before. Applying flexoelectricity to the silicon material (effectively changing the electrical properties due to local deformation of the material, which causes a bandgap change) resulted in a strain effect (elasticity change to the semiconductor crystal structure caused by external stress and other factors, resulting in a change in physical properties) suitable for the semiconductor crystal structure, and the research team discovered it could significantly reduce bandgap energy to the same as or lower than infrared light energy. The research team used this to identify the light detection principle that maximizes optical response in the infrared region and succeeded in developing an optical sensor structure.

The research team used a gold probe tip to sequentially apply micropressures of a few micro-Newtons in size to a diameter range of 960 micrometers to induce a sharp decrease in bandgap energy. Through this, it was possible to obtain an excellent device with high sensitivity, detection rate, and response rate to the light of infrared wavelengths using only a silicon semiconductor. This performance is superior to the conventional commercially-available infrared detection device.

In particular, the research team used an alternating photocurrent in the photosensor to drive the device, using the photoelectric effect to negate the need for external power supply through absorption of infrared incident light that quickly turns off and on repeatedly. The detection speed of the device developed by the research team is 100 microseconds (0.1 msec), enabling high-speed detection, and using an atomic force microscope, it was confirmed that the same flexoelectricity effect-based infrared detection can be implemented at a size of 30 nanometers.

“There is an important academic and technical significance in that we achieved infrared detection with an ultra-high sensitivity that was previously impossible with general-purpose silicon (Si) material widely used for sensors and integrated circuits,” said Prof. Seo. He further explained, “If applied, it will be possible to integrate a high-speed, high-sensitivity infrared detection device into an existing silicon integrated circuit, which can result in a low-cost, high-performance IoT sensor.”

This research was carried out with the support of the Mid-Career Researcher Program and Young Researcher Program hosted by the Korean Ministry of Science and ICT and the National Research Foundation (NRF). A patent application is in progress.

* Image provided by WILEY-VCH